With over 250 years of experience in the world of ink, hubergroup is one of the leading international ink specialists. However, what makes us special is that as a family business we focus on your unique requirements. We work closely with your processes and reflect daily on how we can contribute to your success. For us, it’s not important that we're the biggest. We want to be the best.

We are all-rounders

But in the printing sector, we are experts

Whether commercial printing, packaging printing, newspaper printing or security printing, hubergroup offers a wide variety of products and services for your pressroom. Thanks to our many years of experience and the close working relationships that we establish with our customers, we fully understand your processes and the challenges that you face on a daily basis.

We therefore focus on developing solutions and technologies that make your everyday work easier. Whether that is with an ink series such as ECO-PERFECT-DRY, which allows fast post-print processing of your printed products, with technologies, which makes your printed packaging even safer, or with services which simplify your operations.

The main drivers behind our new developments are above all product safety, quality and sustainability. We produce up to 90% of our raw materials ourselves. We are therefore able to define our own quality and environmental standards and our chemical experts are always on hand to assist you when you need them – because we are not just a printing ink manufacturer, we are a partner that shares their knowledge with you.

255 years full of innovations

There’s too much to mention, isn’t there?

Since the early days of hubergroup in 1765, having the courage to try something new has played an important role in the company. Mathias Mittermayer, a trained mason, decided at that time to forge a new path in ink production. On 29th November 1765, he registered his first patent for the production of the natural inks Vienna Varnish (a rich reddish-yellow colour), Prussian Blue, Carmine Red and the yellow colour of the Munich coat of arms, which he had permission to sell in Germany and abroad. So it was, in Haidhausen a district in Munich, that he laid the foundations for today’s hubergroup.

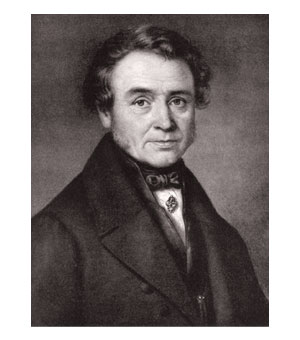

Since then, of course, a lot has changed: in 1780, Mittermayer’s son-in-law Georg Huber took over the company and successfully expanded the business before he passed it over to his son Michael Huber (l.) in 1815. Led by Michael Huber, the company eventually became the first German printing ink manufacturer. Huber recognised the future relevance of printing inks early on thanks to his close association with Alois Senefelder, the inventor of lithography (stone printing). In the following years, the company, known as Michael Huber München, went on to become internationally renowned.

The subsequent Huber generations also worked passionately to expand their ink business: with new production sites, a continually expanding range and constantly improving manufacturing techniques, Michael Huber München continued to grow. The company even recovered quickly from the decline in production during the two world wars: it built up the production facilities once again and at this point specialised fully in printing inks. The company premises in Haidhausen soon became too small and the headquarters were relocated to Kirchheim-Heimstetten in 1965.

In the 1990s and 2000s, the company achieved success in the international printing inks market with new sites in Europe, South America and Asia. One important milestone was the acquisition of Micro Inks Limited in 2006, because up to this day this enables us to produce a large percentage of the raw materials for our printing inks ourselves. With innovations such as low migration printing inks as well as mineral oil-free and cobalt-free printing inks the company – now called hubergroup – set the environmental standards early on and has therefore become a trendsetter within the printing industry.

Today hubergroup is one of the leading international specialists for printing ink and printing aid solutions and technologies. A contributing factor to this success is having the courage to forge new paths, this plays an important role in our daily work even after more than 250 years. This is the only way that we can continue to develop innovative solutions and technologies for the printing industry.

hubergroup adapts the whole production of sheet-fed offset inks in line with GMP standards

hubergroup becomes the first international printing inks manufacturer to become C2C certified and makes sustainability an industry standard

hubergroup is the first printing inks manufacturer to set the standard and make cobalt-free printing inks.

All the companies are brought together under the brand name hubergroup

By introducing the 10-point MGA guarantee, hubergroup set a new safety standard for printing inks used for food packaging.

The acquisition of Micro Inks Limited enables backward integration: hubergroup now produces a large percentage of the raw materials itself.

Fountain solution concentrates for VOC-free printing are introduced to the market under the names REDUFIX and SUBSTIFIX

MGA inks are introduced to the market

The headquarters are relocated to Kirchheim/Heimstetten

The production facilities are rebuilt after the Second World War and Michael Huber München focuses on specialising solely as a printing inks manufacturer.

Under Michael Huber (I.) the production of printing inks is expanded

Georg Huber takes over and successfully grows the company.

Mathias Mittermayer is granted permission by the electoral court to produce and sell inks